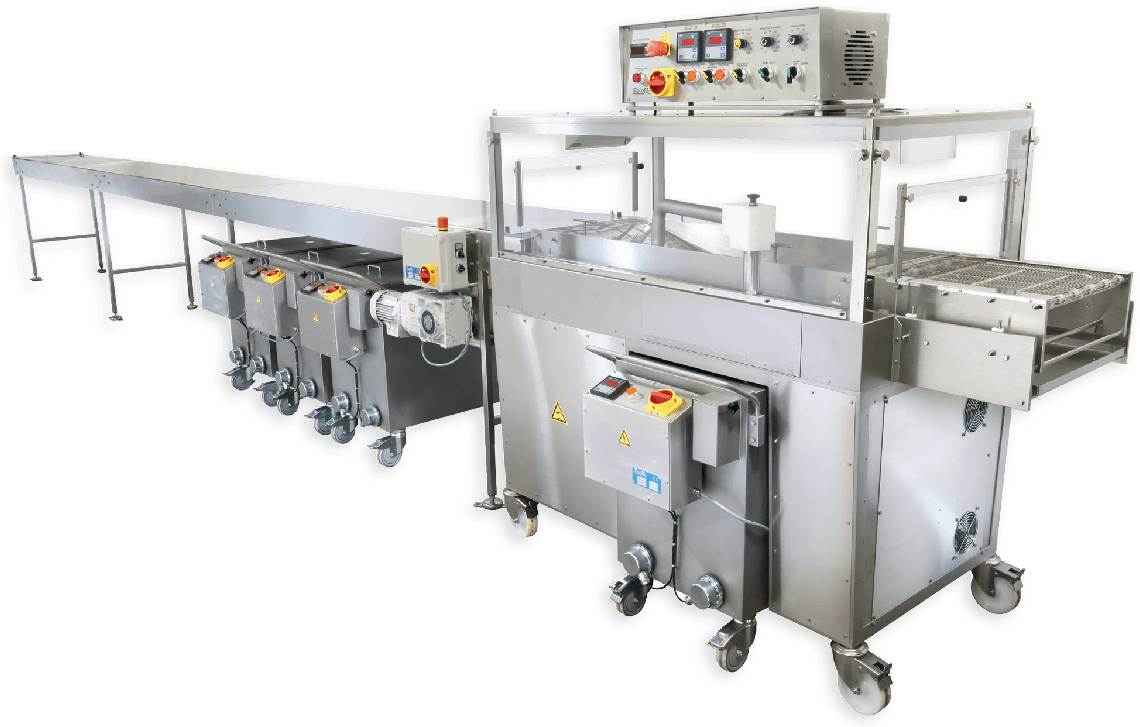

The perfect cheese waxing option for small and medium-sized manufacturers

For more than 30 years, PRO-WAX cheese waxing machinery has operated worldwide. The system has replaced the labor-intensive manual waxing process and provided increased capacity for small and medium-sized manufacturers, enabling them to increase their production by up to 4 times. A typical throughput for 200 gms mini truckles is 70 pieces per minute.

With Pro-Wax cheese waxing machinery, small and medium-sized manufacturers get:

- Uniform appearance from a single pass

- Throughput for 200 gms truckles is 70 pieces per minute

- Enables swift changes between different waxes and colors

- Making your cheese waxing 3-4 times faster than manual production

- Full coating within a size range of 50 gms to 10 kg

Other advantages worth mentioning

A flexible and versatile production unit

PRO-WAX is designed to wax cheese sizes ranging from 50 gms to 2.500 gms. Each cheese gets a full coating (bottom included) and appears nice and uniform from just a single pass through the waxing chamber.

Waxing cheeses up to 10 kg

Wheels or ½ wheels ranging from 2.5 kg to 10 kg can usually be coated too. However, depending on the kind of cheese and specific operating parameters double coating may be necessary.

A swift change of wax colors

In order to coat the cheese with different wax colors, PRO-WAX employs mobile wax tanks, quick-change pumps, and grill belt assemblies to enable fast color changes.

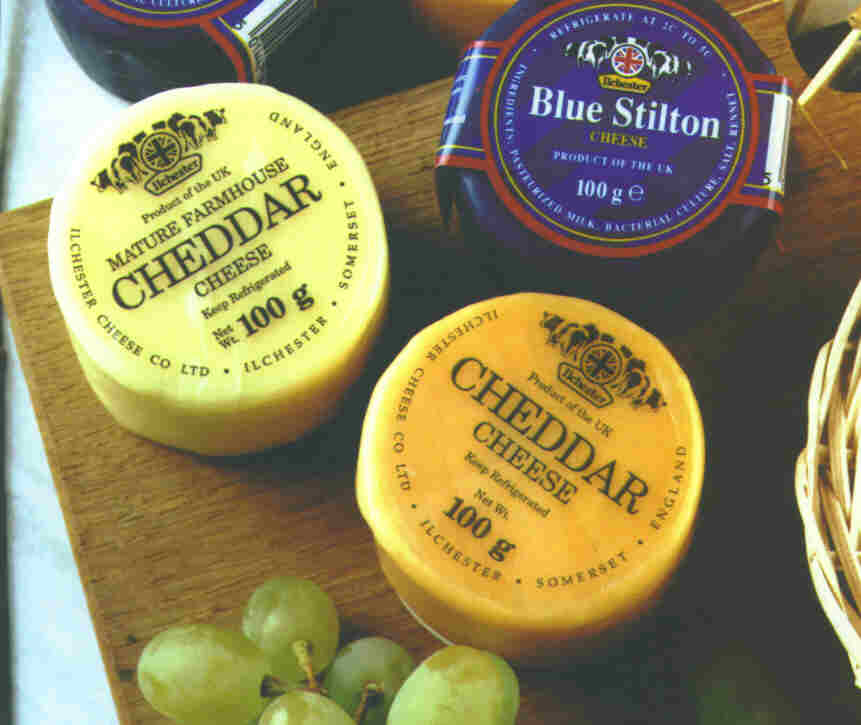

Use different wax colors to enhance your brand

Due to PRO-WAX’s quick readjustment abilities, there are great possibilities for using wax coloring as a brand-enhancing element. Creative use of different wax colors in combination with descriptive product names can bring a strong identity to your cheese brand while preserving productivity.

More than 30 years of cheese waxing experience

Back in the 1990s, Vantage House was approached by a cheese manufacturer at a chocolate machinery exhibition and asked, “…if you can put chocolate on a Mars bar – can you put a wax coating around a cheese?”

While this sounded like a simple transition, the execution proved more of a challenge. Vantage House forwarded the question to their manufacturer of chocolate coating machines, Chocoma, the parent company of Pro-Wax, and that was the beginning of Pro-Wax and the first cheese waxing machines.

Today, small and medium-sized cheese manufacturers worldwide benefit from our machines.

See references“Since then, we at Vantage House have installed and commissioned 50 waxing machines throughout the UK and Ireland, with several companies buying two or more additions as their sales grew. It has been a great joy to see how small cheese artisans have grown their businesses with automatic waxing without compromising the mix in sizes and formats.”

Malcolm Avison, Founder of Vantage House

Would you like to make your cheesing waxing 4 times faster?

Contact us for more information or to get a quote.

Why Choose Pro-Wax: Our expertise in cheese waxing technology sets us apart. We take pride in providing tailored solutions that match your requirements. Our machines are designed to meet the diverse needs of small and medium cheese manufacturers.

Prompt Assistance: We understand the value of your time. Expect a swift response after submitting the form below. Our team is dedicated to promptly addressing your inquiries and providing the information you need.

Let’s Get Started: Take the first step towards enhancing your cheese production process. Fill out the form below, and we’ll contact you shortly.